Mattress Support Cores

The support core is a crucial part of any mattress. It reinforces the bed and prevents the sleeper from sinking too deeply into the surface of the mattress. The support core also influences other important performance aspects such as temperature neutrality, edge support, and durability.

Support cores can be constructed using a wide variety of materials, the most common of which include foam, latex, coils, and air or water chambers. We’ll examine the materials and construction of the most common support core types to help you find the right option for your needs.

What Are Mattress Support Cores?

Located in the base of the mattress, the support core is designed to provide spinal support and stabilize the mattress.

Ideally, the support core should be firm enough to prevent sleepers from sinking in too far, but able to flex sufficiently in order to prevent unnecessary pressure buildup. Some support cores are built using zoned designs, with additional structure in areas that tend to bear more weight.

Depending on the materials used in the support core, a mattress may be more or less supportive, and it may offer advantages such as better airflow, stronger edge support, or less motion transfer.

What Purpose Do Mattress Support Cores Serve?

While the main purpose of a support core is to reinforce the mattress, it also impacts other important aspects of the bed’s performance.

- Even Support: Without a strong support core, areas such as the hips and shoulders can experience a disproportionate amount of pressure. Support cores aim to distribute weight and keep the sleeper’s spine in a neutral position.

- Enhanced Durability: A sturdy support core can help strengthen the entire mattress and extend its lifespan. Quality support cores help protect against premature sagging, sinking, and permanent indentations, which may keep your mattress performing well for longer.

- Temperature Regulation: Although the support core doesn’t come in direct contact with the sleeper, it still provides an important channel for heat to escape. Coil support cores tend to be very breathable, whereas those with a more solid construction may trap heat.

- Motion Isolation: Motion transfer can be bothersome to sleep partners who are sensitive to each other’s movements. People who share the bed may benefit from support cores made from materials like polyfoam and pocketed coils, which react locally to movement and may help cut down on disturbances.

- Noise Reduction: Traditional innerspring designs included moving metal parts that had a tendency to squeak over time. Newer designs feature quieter materials such as polyfoam and latex, which are virtually silent. Innerspring support cores can also be made with pocketed coils, which are wrapped in fabric to reduce noise.

General Mattress Construction

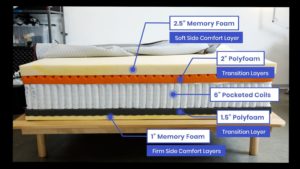

Virtually all mattresses share a basic design, consisting of a comfort section on top of a support system. Some mattresses also have one or more transitional layers between these two sections.

Beyond this standard build, mattresses can be grouped into categories according to the type of materials used to make them. The exact feel of a given mattress, including performance factors like breathability, motion isolation, and responsiveness, further depends on the quality and specific design of that model.

Comfort System: The comfort system typically occupies between 2 and 4 inches of the mattress. Comfort layers can be made using a wide variety of materials, including memory foam, polyfoam, latex, microcoils, and natural fibers such as wool or cotton batting. The type of materials used in the comfort system directly relates to how firm the mattress will feel. The comfort layers should conform closely enough to relieve pressure points, without causing users to sink in too far and feel swallowed by the mattress.

Transitional Layers: Transitional layers are typically made of slightly firmer materials than the comfort system, such as high-density polyfoam, latex, or microcoils. The goal of a transitional layer is to provide a deeper cradle and prevent sleepers from making contact with the hard support core. This layer is usually thinner, between 1 and 3 inches.

Support Core: The support core is responsible for promoting proper spinal alignment. It also provides a base to hold the mattress together. Support cores are usually at least 6 inches thick, constructed using sturdy materials such as steel coils, high-density polyfoam, firm latex, or air chambers. The materials used to make the mattress core are largely responsible for determining what type of mattress it is, whether latex, foam, hybrid, innerspring, or airbed.

Cover: Most mattresses come with a fabric cover, often featuring cotton, polyester, Tencel, or blended fabrics. The cover contributes to the mattress’ breathability and feel, and it may incorporate quilted layers of foam or fibers for added cushioning. Some covers are removable and machine-washable for easier care.

Mattress Support Core Construction

All support cores share the common goal of providing support for the sleeper and the mattress. To this end, support cores are generally built using materials that can absorb and distribute pressure while maintaining their structural integrity.

There are several different types of support cores available on the market today. Foam and latex cores provide a firm and solid base. Innerspring and hybrid cores rely on steel springs, which flex to absorb the pressure as the sleeper moves around on the bed. Less common types of support cores include water bladders and air chambers, which may allow users to adjust the firmness of the support core.

Support Core Measurements

The height of the support core generally corresponds to roughly two-thirds of the full mattress profile. Most mattresses have a profile between 8 and 14 inches, and most support cores fall between 6 and 10 inches.

The thinnest support cores tend to be those made of a single layer of latex or polyfoam. Coil support systems usually require a minimum of 6 inches, plus a few additional inches if they have a polyfoam base layer. Support cores that are thinner than 6 inches may not be suitable for daily use, especially for sleepers who weigh more than 230 pounds.

Support Core Components

In addition to the primary support core, mattress support cores may have a transitional layer, a base layer, or a reinforced perimeter. These components work together to deliver a comprehensive support system for the mattress:

- Transitional Layer(s): Transitional layers rest between the comfort layers and the support core and prevent the sleeper from sinking straight onto the support core. Transitional layers are typically made from materials such as high-density polyfoam, latex, or microcoils.

- Primary Support Core: The primary support core is where most of the bed’s reinforcement comes from. Made of strong materials like steel coils, firm latex, or high-density polyfoam, the primary support core supplies a sturdy base to help promote healthy spinal alignment.

- High-Density Foam Encasement: Some mattresses feature an additional foam encasement around the support core, which helps strengthen the mattress and the perimeter of the bed. Foam encasements are most common in innerspring, hybrid, and airbed mattresses.

- Base Layer: Innerspring and hybrid mattresses often have a base layer to help provide pushback for the coils and prevent sleepers from bottoming out. Most base layers are relatively thin, constructed using 1 or 2 inches of high-density polyfoam.

Unique Support Core Designs

Airbeds and flippable mattresses break from convention in order to give sleepers more flexibility with firmness levels.

Adjustable Air Chambers: Airbed mattresses have support cores made with air chambers, providing a firmer feel when more air is pumped in and a softer feel when air is let out. Traditionally, users had to manually add or remove air from the chambers to alter the firmness level. Today, many airbeds come with remote controls or apps that allow sleepers to adjust the firmness level more easily.

Flippable Mattresses: Flippable mattresses are constructed using a different comfort layer on each side of the support core, allowing either side of the mattress to be used as the top. Most flippable mattresses have a different firmness level on each side. In flippable mattresses, the support core consists of the firmer layers in the middle of the mattress, as well as the comfort layers from the side that’s placed face-down.

Mattress Support Core Materials

The vast majority of mattresses have a support core containing either steel coils, high-density polyfoam, or latex. More rarely, shoppers may come across a model containing air or water chambers in the support core. Each material confers certain benefits and drawbacks, and understanding how different support core materials alter a bed’s performance can help you predict how a mattress will feel.

Coils

Historically, most mattresses were constructed using a coil support core. The coils are designed to flex when pressure is added and return almost immediately to their original shape when pressure is lifted. As a result, coil support cores generally offer decent ease of movement with a somewhat bouncy feel.

The sturdiness of the metal coils can make them particularly beneficial for sleepers who weigh over 230 pounds. Most coil support cores also regulate temperature well, as air can freely travel through the coils.

Coil support cores are still very common and are mainly found in innerspring and hybrid mattresses. They are typically made of steel, which may be tempered for added strength and durability. Most mattresses made today fall into one of four categories:

- Bonnell Coils: Formerly the industry standard, the Bonnell coil pattern consists of hourglass-shaped steel coils that are knotted at the ends. The coils are joined to each other along the top and bottom by special wires known as helicals, which help distribute weight to the neighboring coils for a more supportive feel. Bonnell coils may also feature stronger wires along the perimeter for better edge support.

- Offset Coils: Offset coils also use hourglass-shaped steel coils that are joined together with helical wires. However, offset coils differ in that they are squared off around the top and, sometimes, the bottom edges. This means that the connection to the neighboring coil happens along a flat line, allowing the coils to provide slightly more localized contouring without sacrificing support.

- Continuous-Wire Coils: As the name suggests, continuous-wire coil constructions consist of individual wires that span the entire length of the mattress, connected by helicals. Continuous wire support cores generally contain less metal overall and cost less to produce. They are still quite supportive, but they don’t conform as closely to the sleeper’s body and they may transfer a significant amount of motion across the bed.

- Pocketed Coils: Unlike the other coil types, pocketed coils are not connected to each other. Instead, each coil is wrapped in cloth, allowing the coils to move independently of their neighbors. Popular in hybrid mattresses, pocketed coils tend to reduce noise and isolate motion better than the other coil patterns. These coils may also be referred to as Marshall coils or individually wrapped coils.

An element of innerspring mattresses that shoppers typically associate with enhanced durability is the coil count, which refers to how many coils are in the mattress. Mattresses may have a total coil count of anywhere from 300 to more than 1,000, depending on the type of coils and the mattress design. Mattresses with low coil counts are often said to wear out more quickly, though this is only one factor among several that contributes to the overall quality of the coils.

Gauge, or a coil’s thickness, is another factor that can impact how the support core will feel. High-gauge coils are thinner and require less pressure to compress, while low-gauge coils are thicker and have a firmer feel. Most mattress coils range between 12-gauge and 17-gauge.

The firmness and durability of the mattress can also be affected by the quality of the steel, whether or not it has been tempered, the number of turns per coil, and any variations in the coil design. For example, some mattresses use thicker coils around the perimeter to minimize sinkage.

Coil Types

| Bonnell | Offset | Continuous-Wire | Pocketed | |

|---|---|---|---|---|

| Typical Cost | $ to $$ | $$ to $$$ | $ | $$ to $$$ |

| Typical Coil Count | 400 to 600 | 600 to 2,000 | 400 to 800 | 800 to 1,200 |

| Typical Gauge | Low to High | Medium to High | Medium to High | High |

| Shape | Hourglass | Hourglass with one or more squared edges | One wire per row, twisted into columns | Cylindrical and individually wrapped in cloth |

| Joining Agent | Metal Helicals and Wire Extensions | Metal Helicals | Metal Helicals | Hot Glue |

| Advantages |

|

|

|

|

| Disadvantages |

|

|

|

|

Coil Support Core Pros and Cons

| Pros | Cons |

|---|---|

|

|

Polyfoam

Polyurethane foam, commonly known as polyfoam, is a versatile material that can take on many different attributes depending on how it is made. This material is traditionally synthesized from petrochemicals, though some manufacturers are starting to incorporate soybean and other materials in an effort to reduce the foam’s environmental impact.

Polyfoam can form the bulk of the support core, or it can form a base or encasement for other materials such as coils. Mattresses made with full polyfoam support cores are generally referred to as foam mattresses. These mattresses usually have polyfoam or memory foam in the comfort section as well.

The foam’s density greatly influences how well it performs in a support core. A denser foam has a higher proportion of material within the same space, and can withstand higher levels of compression before its structure is permanently altered. Support cores typically use high-density polyfoam to give the mattress a durable, supportive structure. Polyfoam density is usually expressed in pounds per cubic foot, or PCF. Support cores should have a density of at least 1.5 PCF, and preferably 1.8 PCF or higher.

High-resiliency polyfoam is the most durable and supportive type of polyfoam, but it is rarely seen due to its higher expense. To qualify as high-resiliency polyfoam, the material not only needs to have a density of at least 2.5 PCF, but it must also have a compression modulus of at least 2.4. The compression modulus refers to the ability of the foam to tolerate pressure without suffering permanent deformations.

Polyfoam Types

| Low-Grade (Conventional) | 1.5 PCF or Lower | 1.8 to 2.0 | $ |

| Medium-Grade (High-Density/HD) | 1.5 to 2.4 PCF | 2.1 to 2.3 | $$ |

| High-Grade (High-Resiliency/HR) | 2.5 PCF or Higher | 2.4 or Higher | $$$ |

Polyfoam Support Core Pros and Cons

|

|

Latex

Latex mattresses have become popular for their durable springiness and gently conforming feel. Natural latex is manufactured using a white liquid harvested from rubber trees. Latex can also be made synthetically using a chemical called styrene butadiene. Environmentally conscious shoppers should look for latex that is certified natural or organic.

Whether synthetic, blended, or natural, latex can be processed using either the Dunlop or the Talalay method. The simplest method is the Dunlop method, in which the latex liquid is whipped and then placed in a mold for baking. This method allows sediment to sink as it sets, making Dunlop latex denser on the bottom. Dunlop is more commonly used in support cores and transitional layers.

In the Talalay method, the whipped liquid is vacuum-sealed, flash-frozen, and then baked. As a result of these extra steps, Talalay latex has a more uniform distribution, yielding a light and airy material with some bounce. Talalay latex is often softer and typically reserved for comfort layers in mattresses.

Knowing the indentation load deflection (ILD) of the latex can help shoppers determine how the material will feel. A higher ILD indicates that more pressure is required to compress the latex, meaning the mattress feels subjectively firmer.

Latex Types

| Extra Soft | 16 or Lower | Close conforming and considerable sinkage | Comfort Layers |

| Soft | 17 to 21 | Conforming with noticeable sinkage | Comfort Layers |

| Medium Soft | 22 to 26 | Moderate conforming and sinkage | Comfort Layers |

| Medium | 27 to 31 | Limited conforming and sinkage | Comfort Layers and/or Support Core Layers |

| Medium Firm | 32 to 36 | Minimal conforming and sinkage | Support Core Layers |

| Firm | 37 or Higher | Sinks and conforms minimally, if at all | Support Core Layers |

Latex Support Core Pros and Cons

|

|

Air Chambers

Though airbeds are a slightly less common option, they have a unique feel and allow users to customize them on a nightly basis. These beds use air chambers as their support core. Using an air pump, sleepers can add air to increase the firmness, or release air to make the surface softer. The air chambers typically have additional comfort layers on top.

Most airbeds sold today have a separate air chamber for each sleeper so that each person can adjust their side of the bed to their desired firmness level. Airbeds may also have multiple air chambers that provide targeted support for different parts of the body.

Airbeds may be controlled through manual settings, or through remote or app-based controls which offer the opportunity to adjust the firmness of the bed in real time.

Air Chamber Support Core Pros and Cons

|

|

Water Bladders

As one of the first mattress types to offer varying firmness levels, waterbeds became popular in the latter half of the 20th century. Their popularity declined along with the rise in memory foam and other materials that offered similar advantages with less maintenance required.

Waterbeds can be either hard-sided or soft-sided. Hard-sided waterbeds are supported by a sturdy frame and platform, made of wood or another durable material. Soft-sided waterbeds feature foam and fabric frames and require a separate sturdy foundation to rest upon, which can be a costly investment.

The support core of a waterbed is composed of water bladders. In free-flow waterbeds, all the water is contained in one bladder. This design often leads to ripples throughout the night, which can be a unique sensation that may be bothersome or noisy. By contrast, waveless waterbeds distribute the water among multiple bladders. This design can help minimize rippling, especially when the compartments are padded with foam or air cells.

A major draw of waterbeds is the ability to control the water temperature using manual controls, a remote control, or an app.

Water Bladder Support Core Pros and Cons

|

|

Support Core Materials Compared

The materials used in the support core contribute significantly to the overall feel and performance of your mattress. Together with the comfort layers, the support core influences key aspects such as durability, temperature neutrality, and motion isolation. Although the performance of a mattress depends on its individual design and materials, it can be helpful to compare how the general types of support cores stack up.

| Used in | Innerspring and Hybrid Mattresses | Foam mattresses, or as a supplemental base for innerspring, hybrid, and airbed mattresses | Latex Mattresses | Airbeds | Waterbeds |

| Availability | Very Common | Very Common | Common | Less Common | Less Common |

| Durability | Good to Very Good | Fair to Good | Very Good | Good to Very Good | Good |

| Conforming | Fair to Good | Good to Very Good | Good to Very Good | Very Good | Good to Very Good |

| Pressure relief | Fair to Good | Good to Very Good | Good to Very Good | Very Good | Good to Very Good |

| Motion isolation | Poor to Good | Good to Very Good | Fair to Good | Fair to Good | Fair to Good |

| Noise | Poor to Fair | Very Good | Very Good | Poor | Poor to Fair |

| Temperature regulation | Very Good | Poor to Fair | Good to Very Good | Poor to Fair | Good to Very Good |

Still have questions? Ask our community!

Join our Sleep Care Community — a trusted hub of sleep health professionals, product specialists, and people just like you. Whether you need expert sleep advice for your insomnia or you’re searching for the perfect mattress, we’ve got you covered. Get personalized guidance from the experts who know sleep best.