Mattress Comfort Layers

Mattresses are typically layered. While each layer has a specific function, they all work in tandem to give a mattress its overall feel.

Comfort layers are the topmost sections of a mattress, and they significantly impact how a sleeper experiences their bed. If a mattress has more than one comfort layer, they’re collectively referred to as a comfort system.

The best mattress for any given sleeper features a comfort layer or comfort system that provides adequate cushioning without feeling too soft or sinking excessively. Both material variety and quality dictate how well a mattress performs across different categories. Construction methods also influence mattress pricing. Knowing the potential benefits and drawbacks of different materials and composition techniques can help you pick the most appropriate mattress.

What Are Mattress Comfort Layers?

As the name suggests, comfort layers are designed to make the sleeping experience as enjoyable as possible. Softer, close-conforming materials cradle the body and redistribute pressure, while firmer options limit sinkage to promote proper spinal alignment.

Beyond adding cushioning and pressure relief, comfort systems can isolate motion, muffle noise, and regulate temperature. They also serve as a necessary barrier between your body and the firmer support system. However, their overall performance depends on the materials, firmness, and thickness.

What Purpose Do Mattress Comfort Layers Serve?

Positioned close to the body, comfort layers directly influence how a mattress feels. Because support cores consist of dense, firm materials, softer layers are placed on top. The extent to which the sleeper sinks into a bed is largely determined by the mattress’ comfort system. Comfort layers serve several key purposes.

Cushioning: A durable mattress requires a robust support core, but sleeping directly on these exceptionally firm materials could result in aches and pains the next morning. Comfort layers cushion the body and essentially act as a buffer between the sleeper and the core.

Pressure Relief: Comfort layers are typically engineered to contour to the body and spread out its weight to lessen the discomfort caused by sharp pressure points, which are common in the shoulders, hips, and back. Materials like memory foam, polyfoam, latex, and/or minicoils can adjust to the sleeper’s shape and reduce pressure buildup.

However, the ideal comfort system should still be firm enough to prevent the heavier parts, like the hips, from sinking too deeply into the mattress and throwing off spinal alignment. Some comfort systems are also zoned with targeted firmness areas designed to balance support and pressure relief.

Motion Isolation: Motion transfer occurs when movement on one part of the bed is experienced on its opposite end, which can be problematic for anyone sharing a bed. Robust comfort layers can absorb and isolate motion well to prevent vibrations from spreading, resulting in less disturbance for sleep partners.

Noise: Certain mattress materials are quieter than others, with all-foam and all-latex models being virtually silent. The coil systems found in innersprings and hybrids could creak as they age, but comfort layers made from foam, latex, and/or fiber help muffle sounds.

Cooling: Comfort layers often utilize cooling technology, like gel infusions, phase change materials, and open-cell constructions to promote airflow and/or dissipate excess heat. Breathable covers can also prevent sleepers from overheating by allowing air to circulate more freely through the mattress.

General Mattress Construction

Most mattresses consist of multiple layers, each of which serves a specific function. Collectively, these layers give a mattress its unique feel. Every material and construction method has possible benefits and drawbacks, but understanding their qualities can help you select the most suitable mattress based on your needs.

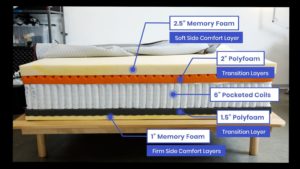

Comfort layers are located at the top of a mattress and combine to form a bed’s comfort system. Most comfort layer materials offer ample cushioning while conforming to the body to relieve pressure. Mattresses of average height typically contain one or two comfort layers, while taller models might contain three or more. Firmer mattresses usually have comfort systems that measure 1 to 2 inches thick, while softer models might be 4 inches or more.

Just below the comfort system is a transitional layer that functions as a buffer between the sleeper and the sturdy support core. Made from firmer materials that average between 1 and 3 inches thick, the transitional layer also deepens the contouring while limiting excess sinkage. Transitional layers are often made from medium- to high-density polyfoam, latex, or microcoils.

Next is the support core, which consists of denser and firmer materials designed to stabilize the mattress and resist sagging. The support core is usually the most substantial part of the mattress and typically ranges between 6 and 10 inches thick. Innersprings and hybrids use sturdy steel coils for their cores, while all-foam models use high-density polyfoam, and natural latex models typically use Dunlop latex.

Lastly, a mattress is usually encased in a cover made from cotton, wool, polyester, Tencel, or other fabric. Some designs, such as pillow-tops, include plush padding by quilting foam or fiber layers directly into the cover.

Mattress Comfort Layer Construction

While exact materials and construction methods vary, many mattresses follow a similar formula that includes four main comfort system components: a cover, quilting material, a comfort layer or layers, and a transition layer. Exact materials and construction techniques vary between models, and some may add or subtract components to achieve specific goals.

Comfort Layer Measurements

Most mattresses are between 10 and 15 inches thick in total, while comfort layers generally measure between 1 and 5 inches. A more substantial comfort system doesn’t necessarily equate to a higher quality mattress, but thickness does impact how a bed feels.

Thicker comfort layers tend to be more conforming, which can be beneficial for those prone to aches and pains. For people who don’t enjoy a hugging sensation or who struggle to change positions during the night, thinner comfort layers may be more comfortable and prevent them from sinking in too deeply. Generally, softer mattresses have thicker comfort systems, while firmer models have thinner layers. Most medium firm mattresses have a comfort system that measures 2 to 3 inches thick.

Comfort System Components

The majority of mattresses utilize multiple layers that together form a comfort system.

Cover: The cover envelops a mattress. It can be made from natural fibers, like cotton or wool, or synthetic fabrics, such as polyester or rayon. Some covers can be removed and washed, but most are permanent fixtures of the mattress and should only be spot treated.

Quilting and Padding: The uppermost layer underneath the cover is often quilting or padding that cushions the surface for added comfort. The plushness you initially feel, however, doesn’t necessarily indicate a mattress’ overall pressure relief. As the comfort layer closest to the sleeper’s body, quilting and padding materials are often breathable to allow heat to escape.

Comfort Layer(s): Sometimes referred to as the middle upholstery, this is usually the thickest part of the comfort system and may contain one or more distinct layers. The most traditional materials for this component include memory foam, polyfoam, latex, and/or minicoils or nanocoils. A comfort layer or a combination of several comfort layers is meant to both cradle and support the body, making it one of the most important factors when it comes to pressure relief and spinal support.

Insulator/Transitional Layer: Known as either the insulator or the transitional layer, this component is positioned below the comfort layer(s) and acts as a buffer between the softer quilting and middle upholstery and the dense, firm support core. It can deepen contouring while limiting excess sinkage that could otherwise lead to poor sleep posture.

Unique Comfort Layer Designs

While most mattresses generally follow the above blueprint, there are two types of mattresses with more specialized comfort layers.

Flippable Mattresses: A flippable mattress features a reversible construction that allows sleepers to use either side. Both sides share a common support core but have two distinct comfort systems. Some designs have two different firmness levels, which provides a versatile sleeping experience for those whose preferences may change. Versatility isn’t the only perk when it comes to flippable mattresses. Switching between two sides can delay the cumulative wear-and-tear that occurs when sleeping exclusively on one side.

Dual-Firmness Mattresses: Dual-firmness mattresses have two distinct feels on a standard one-sided model. The mattress is designed to accommodate couples with different firmness preferences. Buyers can usually select the feel of both sides, allowing each partner to select an option that more closely matches their needs and preferences. Separate firmness levels require two distinct comfort systems, so sleepers will likely notice the transition if they lie in the center of the bed.

Mattress Comfort Layer Materials

Comfort layers can be made from an array of materials, but most fall into one of six main varieties: memory foam, polyfoam, latex, natural fiber, minicoils or nanocoils, and buckling column gel. Each material feels and performs differently, which greatly impacts the overall sleep experience.

Memory Foam

Memory foam is a type of polyfoam that was designed by NASA engineers before becoming widely available for commercial use. Also known as viscoelastic foam, memory foam is used almost exclusively in comfort and transition layers because of its conforming nature. Some comfort systems are made entirely of memory foam, while others also add layers of polyfoam, latex, or mincoils.

Memory foam softens in the presence of heat, giving it its characteristic body-hugging sensation and allowing it to cradle pressure points around the shoulders, hips, and lower back. Memory foam cools and returns to its original form when the sleeper leaves the bed.

In addition to providing pressure relief, memory foam also absorbs movement and noise well, making it an excellent choice for couples.

A possible disadvantage of memory foam’s deep contouring is that movement may feel restricted. Traditional memory foam also tends to retain heat because of its denser composition and close hug.

Because many people sleep hot, companies have developed various cooling technologies intended to improve temperature neutrality. One of the most popular types is gel memory foam, which incorporates gel infusions engineered to dissipate excess heat. Infusions of green tea, graphite, copper, and/or bamboo are designed for similar purposes. Phase change surface infusions crafted to wick away heat are also increasingly common.

Manufacturing methods can also affect the feel of memory foam. Varieties with open-cell structures leave extra spaces within the foam, making the material softer and more breathable. In contrast, closed-cell memory foam tends to be firmer and more prone to heat retention.

Memory foam is measured in pounds per cubic foot (PCF), a measure of density that is an important indicator of certain performance factors, like contouring, motion isolation, responsiveness, and temperature control.

Memory Foam Grades

| Grade | Density Range (PCF) | Description | Price Range |

|---|---|---|---|

| Low | 3.9 PCF or Lower |

|

$$ |

| Medium | 4.0 to 5.4 PCF |

|

$$$ |

| High | 5.5 PCF or Higher |

|

$$$$ |

Memory Foam Comfort Layer Pros and Cons

| Advantages | Disadvantages |

|---|---|

|

|

Polyfoam

Polyfoam is short for polyurethane foam. This synthetic material traditionally uses compounds derived from petrochemicals. Most comfort systems formerly consisted of polyfoam, but more and more companies are turning to memory foam and/or latex.

Unlike memory foam, which has very specific qualities, the performance of polyfoam can vary greatly depending on the production method. This variability makes the material common across all mattress layers.

Two main types of polyfoam are popular for comfort layers: uniform and convoluted. Uniform polyfoam is typically used in quilting and middle upholstery because it has a flat and even surface. Convoluted polyfoam, or egg crate foam, has ridges and is occasionally used in transitional layers. In general, though, convoluted polyfoam is more often used in mattress toppers than in mattresses themselves.

Polyfoam is generally not considered a top-of-the-line material for comfort layers because of its relatively low density. It doesn’t typically contour as deeply as memory foam or latex, and its lower density also means that it may degrade more quickly. As a result, mattresses made with polyfoam comfort layers are usually less expensive than those made with denser alternatives.

Like memory foam, polyfoam is traditionally measured in PCF. The three polyfoam grades are high-resiliency (HR), high-density (HD), and conventional. The compression modulus range, which is the ratio of stress-to-strain, may also be worth noting.

Polyfoam Grades

| Grade | Density Range (PCF) | Compression Modulus Range | Price Range |

|---|---|---|---|

| Low-grade (Conventional) | Less than 1.8 PCF | 2.0 or Lower | $$ |

| Medium-grade (High-density/HD) | 1.8 to 2.5 PCF | 2.1 to 2.3 | $$$ |

| High-grade (High-resiliency/HR) | More than 2.5 PCF | 2.4 or Higher | $$$$ |

Polyfoam Comfort Layer Pros and Cons

| Advantages | Disadvantages |

|---|---|

|

|

Latex

Natural latex is derived from the sap of rubber trees, while synthetic latex uses chemicals derived from petroleum. Blended options are also available. This versatile material known for its durability is found in comfort systems, transitional layers, and support cores.

There are two main methods for producing latex: Dunlop and Talalay. The Dunlop process generates a denser latex that can be used in comfort layers, transitional layers, and support cores. Talalay latex, on the other hand, has a fluffier, more uniform texture that makes it more suitable for comfort and transitional layers.

Because it has lower point elasticity than memory foam, latex spreads the compression over a wider area, creating more of a floating sensation than a hug. This limited sinkage paired with its more breathable composition typically makes latex cooler than memory foam. Latex also has notable bounce, which makes it conducive to sex and movement in general. The tradeoff of springiness, however, is often greater motion transfer.

To be classified as a latex mattress, a model must contain at least one latex comfort layer and a latex support core. A model labeled as natural latex may contain a small amount of synthetic latex. Certified organic latex must contain over 95% certified organic raw material.

Latex’s firmness is measured using indentation load deflection (ILD) rather than density.

Latex Varieties

| Firmness Level | ILD Measurement | Characteristics | Used in |

|---|---|---|---|

| Extra Soft | 16 or Lower | Closely conforming and significant sinkage | Comfort Layers |

| Soft | 17 to 21 | Notable conforming and sinkage | Comfort Layers |

| Medium Soft | 22 to 26 | Moderate sinkage and uniform conforming | Comfort Layers |

| Medium | 27 to 31 | Minimal sinkage and average conforming | Comfort Layers and/or Support Core Layers |

| Medium Firm | 32 to 36 | Very minimal sinkage and minimal conforming | Support Core Layers |

| Firm | 37 or Higher | Little to no sinkage and conforming | Support Core Layers |

Latex Comfort Layer Pros and Cons

| Advantages | Disadvantages |

|---|---|

|

|

Natural Fibers

Natural fibers have gained popularity, often being used as an alternative to memory foam, polyfoam, and latex. Wool, cotton, silk, hemp, horsehair, and coconut coir are the natural fibers most commonly used in comfort layers.

Natural fibers are sought-after for their cushioning, breathability, and durability. They can also be manufactured using sustainable processes.

Natural Fiber Varieties

| Natural Fiber | Description | Characteristics |

|---|---|---|

| Cotton | Cotton is harvested from cotton plants. It is considered organic if it is grown without synthetic agrochemicals. |

|

| Silk | Silk consists of fibers made by silkworms. When used in comfort layers, it is usually combined with other materials, like wool. |

|

| Wool | Wool comes primarily from the fleece of sheep. Like cotton, wool can be organic. Organic options traditionally avoid chemicals and prioritize animal welfare. |

|

| Hemp | Hemp fibers are harvested from the long outer fibers of hemp plants, which are a variety of cannabis. |

|

| Horsehair | Horsehair is seldom used in comfort layers except occasionally in high-end models. |

|

| Coconut coir | Coconut coir consists of fiber extracted from coconut shells. |

|

Natural Fiber Comfort Layer Pros and Cons

| Advantages | Disadvantages |

|---|---|

|

|

Minicoils, Microcoils, and Nanocoils

Manufacturers are increasingly using minicoils, microcoils, and nanocoils in comfort layers. These are typically significantly smaller than the coil cores found in hybrid and innerspring models. Minicoils and microcoils are interchangeable terms that refer to springs measuring between 1 and 4 inches tall. Nanocoils are even shorter and typically don’t exceed .75 inches. For a broader context, most innerspring coils are 6 inches or more.

Because of their size, microcoils and nanocoils have a significantly different feel than standard springs. They contour to the body to relieve pressure while adding bounce and breathability to the comfort system. Microcoils and nanocoils are also commonly encased in foam or fabric, which helps reduce motion transfer. However, microcoil and nanocoil layers usually result in a taller mattress, which might not be suitable for people who prefer low-profile designs.

Some mattresses use zoned coils in their comfort and/or transitional layers to minimize pressure buildup while supporting good posture. In a zoned configuration, thicker (low-gauge) coils are often used in more weight-bearing areas of the mattress, like the shoulders, hips, and midsection. Thinner (high-gauge) coils are positioned under lighter areas, like the head and legs.

Minicoil/Microcoil/Nanocoil Comfort Layer Pros and Cons

| Advantages | Disadvantages |

|---|---|

|

|

Buckling Column Gel

Buckling column gel is one of the newer materials used in comfort layers, and it’s still fairly rare. Derived from mineral oil, buckling column gel is a dry-polymer substance that is applied to a grid of square, hexagonal, round, or H-shaped columns. The elastic polymer columns buckle based on the amount of pressure.

Heavier parts of the body, like the hips and midsection, experience greater pushback, and lighter areas receive more cradling. Comfort layers made with buckling column gel tend to offer exceptional pressure relief while resisting sagging and other signs of deterioration. The material also limits the spread of vibrations and allows ample airflow so that heat can dissipate.

Mattresses made with buckling column gel are still relatively uncommon, which is reflected in their higher price-points. Some people also note a crackling sensation with this type of mattress, though this may improve as it ages.

Buckling Column Gel Comfort Layer Pros and Cons

| Advantages | Disadvantages |

|---|---|

|

|

Comfort Layer Materials Compared

Each type of comfort layer material has specific properties that affect how a mattress performs across a range of categories. We’ll highlight general ratings for the most commonly used materials in comfort layers. It’s important to keep in mind that the overall quality of a mattress depends on more than just the comfort system. Even the highest quality materials might not be able to function optimally if the mattress is poorly designed or constructed.

| Polyfoam | Memory Foam | Latex | Microcoil | |

|---|---|---|---|---|

| Mattress Price Range | $700 to $1,000+ | $900 to $1,200+ | $1,300 to $1,900+ | Varies by Mattress Type |

| Availability | Very Common | Very Common | Very Common | Common |

| Durability | Poor | Fair to Good | Very Good | Good |

| Conforming | Fair to Good | Very Good | Good to Very Good | Good to Very Good |

| Pressure relief | Poor to Fair | Very Good | Good to Very Good | Good to Very Good |

| Motion isolation | Fair to Good | Very Good | Good to Very Good | Good to Very Good |

| Noise | Excellent | Excellent | Excellent | Good to Very Good |

| Off-gassing & odor | Poor to Fair | Poor to Fair | Good to Very Good | Very Good |

| Temperature control | Poor to Fair | Fair to Good | Good to Very Good | Very Good |

Still have questions? Ask our community!

Join our Sleep Care Community — a trusted hub of sleep health professionals, product specialists, and people just like you. Whether you need expert sleep advice for your insomnia or you’re searching for the perfect mattress, we’ve got you covered. Get personalized guidance from the experts who know sleep best.