Mattress Coil Types

To be comfortable, a mattress must provide balanced pressure relief and spinal support. The vast majority of mattresses accomplish this by pairing a sturdy base with a softer comfort section. The materials and design of these layers contribute to the price-point and determine how the mattress performs for different types of sleepers. Among the most common materials used in the support core are mattress coils.

Typically utilized in innerspring and hybrid mattresses, mattress coils are metal springs that are arranged in a pattern to support the weight of the sleeper. There are several different types of coils, each of which is optimized for a different function. In addition to the Bonnell coils, offset coils, continuous-wire coils, and pocketed coils used in the support core, some mattresses also utilize smaller coils in the comfort layers.

Understanding how the different styles of coils contribute to the feel and durability of the mattress can help you identify the type that is best for you.

What Are Mattress Coils?

Mattress coils are metal springs that support the mattress and form a durable surface on which to sleep. They’re designed to flex in response to pressure and movement, providing progressively firmer support as more pressure is placed on the mattress.

Most mattress coils are constructed with tempered steel. This process utilizes repeated heating and cooling to improve the coil’s resiliency and enable it to keep regaining its original shape despite prolonged use.

Coil-based mattresses tend to be responsive and fairly durable. As the coils leave room for airflow, they also sleep cooler than all-foam mattresses. Coil-based mattresses may be more or less supportive depending on factors such as the coil type, gauge, total coil count, and overall mattress design.

The four primary types of coils used in mattress support cores include Bonnell coils, offset coils, continuous wire coils, and pocketed coils. Some mattresses also use microcoils, nanocoils, and minicoils in the comfort or transitional layers. Within the major types of coils, there may also be slight variations in design.

We’ll discuss what you can expect from each type of coil to help you choose the best mattress for your sleeping style.

Mattress Coil Types

Each mattress coil style offers certain advantages and disadvantages for different sleeping positions, body types, and budgets.

| Bonnell | Offset | Continuous-Wire | Pocketed | |

|---|---|---|---|---|

| Typical Cost | $ to $$ | $$ to $$$ | $ | $$$ |

| Typical Coil Count | 400 to 600 | 500 to 2,000 | 400 to 800 | 800 to 1,200 |

| Typical Gauge | Low to High | Medium to High | Medium to High | High |

| Shape | Hourglass | Hourglass with squared sides | Single wire formed into loose coils | Cylindrical springs encased in fabric |

| Joining Agent | Metal Helicals and Wire Extensions | Metal Helicals | Metal Helicals | Glue or Other Bonding Materials |

| Advantages |

|

|

|

|

| Disadvantages |

|

|

|

|

Bonnell Coils

Bonnell coils have an hourglass shape that is wider on the top and bottom than in the middle. The thinner portion is designed to flex in response to minimal pressure, while the thicker portion can stand up to greater pressure. Each coil is knotted at the end and connected to the neighboring coils via a network of thin, spiral-shaped helical wires.

Since Bonnell coils are interconnected, they move as a single unit. This allows them to provide more support, but it means they can’t adjust to different weights and sleep positions as well as other mattress coil styles. Friction from the coils may also produce some noise.

Bonnell coils were the original type of mattress coils used to make mattresses. They’re also one of the least expensive types of mattress coil. Bonnell coils are fairly firm and they generally have reliable edge support, though they can be prone to sagging in the center of the mattress.

Offset Coils

Offset coils are a derivative of Bonnell coils, sharing their hourglass shape and interconnected helical wires. While offset coils look similar to their predecessors, some key differences make them more responsive, comfortable, and quieter.

Rather than a completely rounded top and bottom, offset coils have squared sides. The coils flex like a hinge under lighter pressure, and provide stronger pushback under an increased load. Offset coils can respond to movement without transferring as much motion to the rest of the mattress, and their ergonomic design may also limit noise.

There are several different variations of offset coils, such as designs with hinges on both sides, or the top and bottom, or offset coils that do not have knots. Offset coils are more costly to manufacture than Bonnell coils, which can drive up the price of the mattress as a whole.

Continuous Wire Coils

Continuous coils are constructed with a single wire, formed into rows of loose coils that are connected by helical wires. This straightforward design is highly durable and inexpensive.

Helical wires throughout the frame provide even spacing for the coils. This helps limit motion transfer, though since they’re tightly connected, continuous wire coils may still transmit some movement when responding to pressure. For the same reason, continuous wire coils are not as quiet as offset coils.

Continuous wire coils are firm and stable, but they don’t offer the same level of contouring as offset coils. They work well in mattresses with thick comfort layers. Continuous coils require less time and money to produce, and they are typically less expensive than other coil types.

Pocketed Coils

Pocketed coils consist of multiple smaller coils that are individually wrapped in fabric. The fabric sleeves are sewn or glued together, allowing each spring to move independently within its fabric casing. Also called Marshall coils, pocketed coils are particularly common in hybrid mattresses.

As each coil moves only when pressure is placed directly on it, pocketed coils are better able to contour to the shape of the body. This design also gives pocketed coils the freedom to respond to movement without transferring motion to the surrounding coils. Individuals who share a bed are less likely to wake up their partners on a pocketed coil mattress.

Pocketed coils have a cylindrical shape that distributes pressure evenly throughout each spring, so the center holds up better than other types of mattress coils. Compared to hourglass-shaped springs, pocketed coils are typically less vulnerable to degradation.

The more complex construction of pocketed coils often commands a premium price. However, while individually wrapped coils are more expensive than the other coil types, they also tend to be more durable and supportive.

Microcoils, Nanocoils and Minicoils

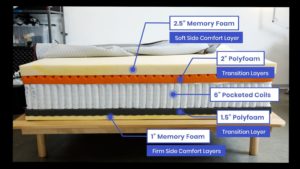

Microcoils, nanocoils, and minicoils are most often utilized in the mattress’ comfort or transitional layers. These small springs are engineered with flexible metal wires to increase responsiveness, durability, and support in the mattress.

Whereas most innerspring coils measure about 6 inches tall, microcoils and mini coils are 1 to 3 inches in height. Nanocoils are even smaller, with some measuring less than 1 inch tall. Most microcoils, nanocoils, and minicoils are individually wrapped for better contouring.

Microcoils, nanocoils, and minicoils function as a transition from the comfort section to the support core. Since they are smaller than regular coils, they respond more immediately to pressure, forming a deep cradle for balanced pressure relief and support.

Including these small coils creates more room for airflow in the mattress’ comfort layers, helping reduce heat retention around the body.

Shoppers are most likely to find microcoils, nanocoils, and minicoils in hybrid mattresses. Some mattresses contain multiple layers of coils, while others alternate layers of foam and microcoils.

Coil Count and Coil Gauge

Two factors that impact the performance of innerspring coils include coil gauge and coil count. Coil gauge describes the thickness of the wire, while coil count refers to the total number of springs in the mattress.

Mattress coils are usually between 13-gauge and 17-gauge, with 13-gauge indicating a thicker coil and 17-gauge indicating a thinner coil. Low-gauge coils are firmer and more durable than high-gauge coils, while high-gauge coils are more responsive and flexible.

The total coil count of a queen size innerspring or hybrid mattress can range from 400 to 1,200. Pocketed coil support cores tend to contain multiple smaller coils, whereas Bonnell or offset coils are larger and tend to come in a lower coil count. Some manufacturers reinforce the perimeter of the mattress with additional low-gauge coils to strengthen the edge support.

A good rule of thumb is to avoid coil counts below 400 for a queen size mattress. However, although mattress companies often advertise high coil counts, this measure doesn’t directly translate to a sturdier or more durable mattress. The quality of the metal, whether it is tempered, the height and gauge of each coil, the shape, and the number of turns also affect how firm and supportive the coils feel.

What Purpose Do Mattress Coils Serve?

The primary purpose of mattress coils is to support your body and evenly distribute weight. When included in innerspring and hybrid mattresses, steel coils help stabilize the bed and help keep your spine on an even plane.

Mattress coils contract and expand in response to pressure, helping buoy sleepers and giving the mattress notable bounce. As a result, coil-based mattresses are generally easier to move on than all-foam models.

Because they don’t conform very closely, mattress coils are usually placed in the support core. From this position they can provide deep spinal support, while the comfort layers on top help cushion the sleeper and reduce pressure points.

The exception to this rule is microcoils, minicoils, and nanocoils, which are more often used in the comfort layers. These smaller, more flexible coils have a hybrid function, providing both pressure relief and spinal support.

Coil-based mattresses are popular with sleepers who value bounce and airflow. Mattresses constructed with coil-based foundations can efficiently support high levels of pressure, making them a strong option for sleepers who weigh more than 230 pounds.

Still have questions? Ask our community!

Join our Sleep Care Community — a trusted hub of sleep health professionals, product specialists, and people just like you. Whether you need expert sleep advice for your insomnia or you’re searching for the perfect mattress, we’ve got you covered. Get personalized guidance from the experts who know sleep best.